Oxford Fabric Technical Guide for Luggage & Bag Professionals

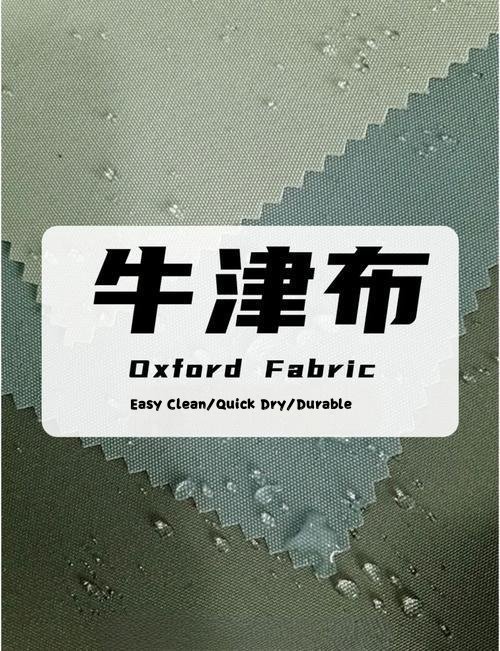

- What is Oxford Fabric?

Oxford fabric is a functional woven textile renowned for its durability, abrasion resistance, structural stability, and ease of maintenance. Its defining characteristic is its distinctive weave structure.

- Core Weave Structure (Oxford Weave):

– Construction: Typically a variant of basket weave or panama weave.

– Yarn Configuration: Warp yarns use two or more fine plied threads, while weft yarns employ a single coarser thread.

– Effect: Creates a characteristic pebbled or checkerboard texture, resulting in a flat surface with visible interlacing points. The tight structure yields high toughness.

- Origin: Named after Oxford University, where it gained popularity for student shirts in the 19th century.

- Key Properties (Industry Focus)

- Durability & Abrasion Resistance: Superior resistance to scuffs, scratches, and wear; ideal for backpacks, suitcases, and travel gear.

- Structural Stability: Minimal deformation or wrinkling; maintains shape rigidity.

- Ease of Maintenance: Stain-resistant (especially post-treatment), easy to clean (wipe/wash).

- Load-Bearing Capacity: High-density weaves (e.g., high denier) support heavy loads.

- Water Resistance (Optional):

– Coatings: PVC (cost-effective, waterproof; stiff, less eco-friendly), PU (softer, eco-conscious, breathable), TPU/TPE (eco-friendly, flexible).

– Laminates: TPU film (high-end waterproof breathable membranes).

– Finishes: DWR (Durable Water Repellent) treatment for beading effect.

- Cost-Effectiveness: More economical than nylon (e.g., Cordura®) or technical polyesters.

- Color Fastness & Printability: Excellent dye affinity, vibrant colors, high color retention.

III. Primary Fiber Composition

- Polyester (PET): Industry dominant. High strength, abrasion resistance, low cost, and colorfastness.

- Nylon (PA): Superior strength-to-weight ratio and softness; higher cost, lower UV resistance. Used for premium/outdoor bags.

- Cotton: Rare in modern luggage due to poor abrasion resistance, wrinkling, and weight. Limited to vintage styles/lining.

- Blends (e.g., Poly-cotton): Uncommon in functional luggage.

- Key Specifications (Procurement Criteria)

- Denier (D):

– Indicates yarn thickness. Higher denier = thicker, heavier, more durable fabric.

– Common Ranges:

– Lightweight: 150D, 210D (sling bags, linings)

– General Use: 300D, 420D, 600D (backpacks, duffels, laptop cases)

– Heavy-Duty: 900D+, 1680D (suitcases, military/tool bags)

– Note: Denier typically references warp yarn (e.g., “600D Oxford”).

- Ply Count (e.g., 2×2, 3×1):

– Denotes yarn twisting (e.g., 2×2 = 2-ply warp + 2-ply weft). Higher ply = greater thickness/durability.

- Thread Count (Density):

– Threads per inch (TPI) or per 10cm (e.g., 190T). Higher density = tighter weave, better abrasion/water resistance.

- Grammage (GSM/g/m²):

– Weight per square meter. Correlates with thickness/density (affected by coatings).

| Denier | Ply | Characteristics | Typical Applications |

| 150D | 1×1 | Lightweight, flexible | Lining, lightweight totes |

| 210D | 1×1 | Light,moderate strength | Daypacks, shopper bags |

| 300D | 1×1/2×2 | Balanced versatility | Daily backpacks, laptop sleeves |

| 420D | 1×1/2×2 | Dense, enhanced abrasion | Travel bags, suitcase lining |

| 600D | 2×2 | Industry standard | Suitcases, tool bags, duffels |

| 900D+ | 2×2/3×1 | Ultra-heavy-duty | Hardcase shells, expedition gear |

- Finishing Processes

- Coatings:

– PVC: Budget luggage shells.

– PU: Industry standard (bags, suitcase lining).

– TPU/TPE: Premium eco-friendly options.

- Laminates: TPU membranes (high-end waterproof breathable bags).

- Calendering: Heat-pressing for smoothness/water resistance.

- Printing: Pre/post-coating applications.

- Flame-Retardant/UV-Resistant Finishes: Specialty requirements.

- Luggage Applications

– Backpacks: All segments (student, travel, outdoor).

– Suitcases:

– Hard-shell: 600D+ PVC/PU (abrasion-resistant exterior).

– Soft-shell: 420D-600D PU (main fabric).

– Lining: 210D-300D calendered/PU Oxford (ticketing).

– Duffels/Totes/Storage Bags: Water-resistant variants.

– Tool/Equipment Cases: 600D+ with PVC reinforcement.

The following are the products made by our company with Oxford cloth as the main material:

For more products, please visit our company’s homepage

VII. Pros & Cons Summary

| Advantages | Disadvantages |

| Exceptional abrasion resistance | Not inherently waterproof |

| Shape retention | Stiff hand feel (high denier/coating) |

| Easy cleaning | Low breathability (coated fabrics) |

| Cost-effective (polyester-based) | PVC environmental concerns |

| Vibrant color options | Weight (high-density/coated types) |

Add a comment